© University of Liverpool 2019

FIELDWORKSAFETY

Planning for working in quarries

When visiting working quarries it is a legal requirement

that you comply with their safety regulations with respect

to head gear, eye protection, footwear and high visibility

clothing.

This video, featuring some of the activities that take place

in a working quarry, demonstrates why you need the

following equipment:

•

safety helmet

•

ear defenders

•

high visibility clothing

•

quality walking boots

Safety boots with metal toe protection are mandatory in

some quarries. Check the regulations with the quarry or

site manager and ask if specialist footwear will be provided.

In many quarries you are expected to carry gloves with you

in case you need to lift anything. In wet clay and sand pits

safety wellingtons with metal toe protection are advisable.

It is a risk to use inappropriate or inadequate equipment.

Their use may lead to personal injury or injury to others.

Equipment for quarries

Identify the following signs:

•

safety helmets must be worn

•

high visibility vests must be worn

•

safety boots must be worn

•

ear defenders must be worn

Click on each sign to find out more about the equipment

you need for a visit to a working quarry.

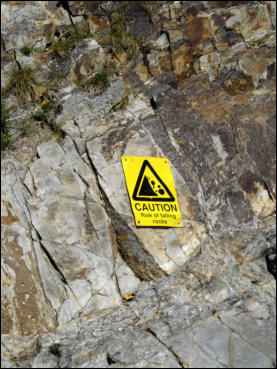

When you see these warning signs

you must ensure that you are

wearing the correct personal

protective equipment (PPE).

Working quarries and pits - hazards

Always obtain prior permission for entry to a working quarry or pit. Unauthorised entry is not only illegal, but you may also place yourself in

danger. On arrival you must contact the site manager (or his deputy). On supervised visits this is usually done by your tutor.

You must:

•

obey any special instructions given by the site manager and/or your tutor

•

stay with all members of the party

•

ask the site manager for permission to collect samples

•

keep away from quarry equipment or controls

•

behave responsibly at all times.

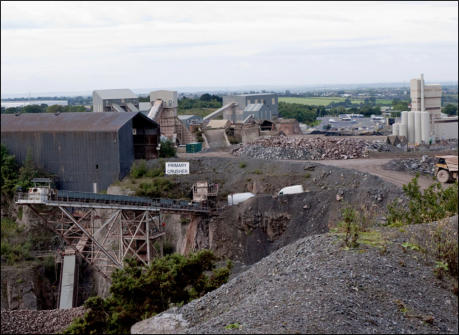

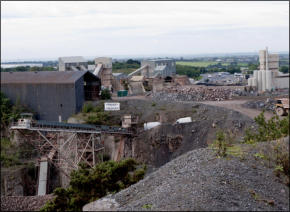

Moving plant

Quarry vehicles loaded with material often move fast and are a hazard. Serious

injury (fractured limbs, crushing, death) could result from impact with quarry

vehicles. To avoid injury you must remain alert and ensure that drivers and

plant operators are aware of your presence at all times.

Remember: When you are crossing quarry roads, quarry vehicles have priority.

Unstable quarry faces

Unstable quarry faces present a hazard

because there is risk of rock faces collapsing or

rock falling from the quarry face. Think about

possible consequences if these events

happened and do remember that unstable

faces may not be clearly marked as a hazard.

Assess the stability of the face yourself and do

not go near the face if it appears to be

unstable.

Piles of rock & quarry waste tips

Rock piles may provide rock samples that are otherwise

inaccessible, but such piles may be unstable. There is risk

of piles collapsing and chances of you sustaining sprain

and/or crush injuries and possibly resulting in injury to

others. Assess the stability of rock piles. Keep away if they

are unstable.

Remember: In quarry waste tips there is also risk of

contact with hazardous materials which may cause burns

or illness.

Settling ponds and mud lagoons

Working (and disused) quarries may have settling ponds or sludge

lagoons. These may appear as pools, but more often they are muddy

ponds partly obscured by a crusty skin (or vegetation in a disused

quarry). Always go round these areas. There is risk of sinking in such

ponds, resulting in entrapment, exposure, suffocation or drowning.

Slopes & faces in pits

Slopes and faces in sand, gravel or soft sediment pits are potential

hazards. Steep slopes may be unstable, particularly in wet conditions.

There is risk of slumping or collapse of faces. These may result in

burial, entrapment, suffocation or death. Avoid climbing such slopes

and faces to reduce the risk of avalanching material onto others

working below you in the pit.

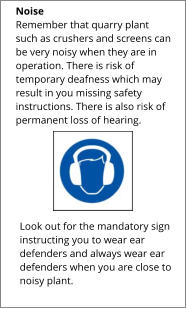

Look out for the mandatory sign instructing

you to wear ear defenders and always wear ear

defenders when you are close to noisy plant.

Noise

Remember that quarry plant such as crushers

and screens can be very noisy when they are

in operation. There is risk of temporary

deafness which may result in you missing

safety instructions. There is also risk of

permanent loss of hearing.

Confrontation in quarries and pits

You are likely to find yourself in a confrontational situation in a

working quarry if you haven't obtained permission to enter or

have placed yourself in danger by ignoring safety instructions.

You will be excluded from the site. To avoid further

embarassment you must respond calmly and leave the site

immediately if requested to do so by someone in authority.

Blasting

Blasting occurs in most hard rock quarries. On arrival at the

quarry you will normally be told about timings of blasting,

warning signals, safety procedures and the location of safe

refuges.

There is risk of injuries from shock waves, noise and flying

rock fragments. Think about the possible consequences of

these injuries.

Conveyors and crushers

Entrapment and high noise levels are risks

associated with conveyors and crushers. These

pieces of equipment are noisy and you may find it

difficult to hear safety instructions or end up with

temporary loss of hearing.

Fractured limbs, crushing and death can occur as a

result of limbs and clothing becoming trapped in the

moving parts of conveyors and crushers. Stay clear

of moving equipment. Never touch controls and do

not attempt to pick samples from a moving

conveyor.

Disused quarries - hazards

This is a view of a disused slate quarry in Snowdonia.

Many of the hazards associated with working quarries may be seen here.

You must ensure that you wear a safety helmet in abandoned quarries and good quality boots with firm ankle support and

good toe protection.

Click on each hotspot to remind yourself about these hazards and to find out about additional hazards in abandoned quarries.

These images highlight some of the

additional hazards presented by disused

quarries.

When you are working in disused quarries

you must always:

•

wear a safety helmet

•

wear good quality walking boots with

good ankle support

•

assess the stability of the quarry face

•

beware of animals and nesting birds on

the quarry ledges.

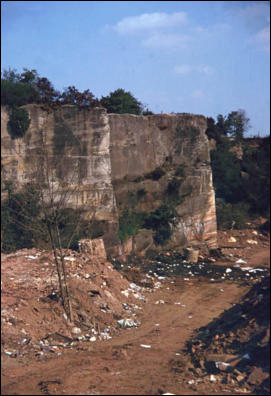

Quarry used as a landfill site

This is a quarry in Storeton, Wirral. Sandstone was quarried at this site, but after the quarry was closed it was used as a landfill site. Some of the materials dumped in old quarries may be hazardous and you should avoid contact with rusty metal or leaking containers to avoid risk of flesh wounds, burns and skin or eye irritation. Note the additional hazards in this quarry where there are overgrown areas and steep rock faces.

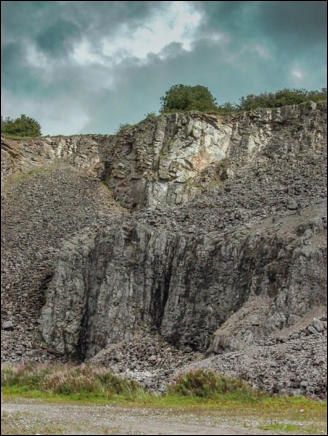

Unstable quarry faces

This shows Park Hall Quarry in Staffordshire. Originally the

quarry was mainly worked for the pebble beds which were

used as aggregate. Park Hall is a SSSI (Site of Special

Scientific Interest) and National Nature Reserve (NNR) for

its geology.

Two of the hazards that are shown in this image are:

•

steep unstable quarry faces

•

overgrown faces.

Disused quarries - additional hazards

Rock falls

This is a disused limestone quarry in North Wales.

The main hazard here is rock falling from the steep rock

faces forming unstable piles of angular limestone

fragments at the base ot the rock faces.

Steep rock faces

This is one of the Ercall quarries in Shropshire. The quarry was worked for

aggregates until 1986.

The steep rock faces left after quarrying ceased are a hazard. An additional

hazard is that the steep rock faces are now partially overgrown and these

areas may shelter snakes and insects.

Remember:

When you are visiting a working quarry it is a legal requirement

that you comply with the safety regulations for that quarry.

Check with the site manager if specialist footwear will be provided.

© University of Liverpool 2019

FIELDWORKSAFETY

Planning for working in quarries

When visiting working quarries it is a legal requirement that you comply with their safety

regulations with respect to head gear, eye protection, footwear and high visibility clothing.

This video, featuring some of the activities that take place in a working quarry, demonstrates

why you need the following equipment:

•

safety helmet

•

ear defenders

•

high visibility clothing

•

quality walking boots

Safety boots with metal toe protection are mandatory in some quarries. Check the regulations

with the quarry or site manager and ask if specialist footwear will be provided.

In many quarries you are expected to carry gloves with you in case you need to lift anything. In

wet clay and sand pits safety wellingtons with metal toe protection are advisable.

It is a risk to use inappropriate or inadequate equipment. Their use may lead to personal injury or

injury to others.

Identify the following signs:

•

safety helmets must be worn

•

high visibility vests must be worn

•

safety boots must be worn

•

ear defenders must be worn

Click on each sign to find out more about the

equipment you need for a visit to a working quarry.

Remember:

When you are visiting a working quarry it is a

legal requirement that you comply with the

safety regulations for that quarry.

Check with the site manager if specialist footwear

will be provided.

Equipment for quarries

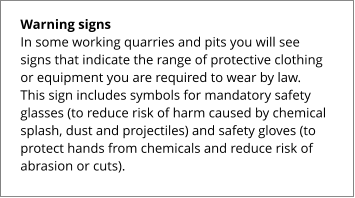

Warning signs

In some working quarries and

pits you will see signs that

indicate the range of protective

clothing or equipment you are

required to wear by law. This sign

includes symbols for mandatory

safety glasses (to reduce risk of

harm caused by chemical splash,

dust and projectiles) and safety

gloves (to protect hands from

chemicals and reduce risk of

abrasion or cuts).

Working quarries and pits - hazards

Always obtain prior permission for entry to a working quarry or pit. Unauthorised entry is not only

illegal, but you may also place yourself in danger. On arrival you must contact the site manager (or

his deputy). On supervised visits this is usually done by your tutor.

You must:

•

obey any special instructions given by the site manager and/or your tutor

•

stay with all members of the party

•

ask the site manager for permission to collect samples

•

keep away from quarry equipment or controls

•

behave responsibly at all times.

Moving plant

Quarry vehicles loaded with material

often move fast and are a hazard.

Serious injury (fractured limbs, crushing,

death) could result from impact with

quarry vehicles. To avoid injury you must

remain alert and ensure that drivers and

plant operators are aware of your

presence at all times.

Remember: When you are crossing

quarry roads, quarry vehicles have

priority.

Unstable quarry faces

Unstable quarry faces present a hazard because

there is risk of rock faces collapsing or rock falling

from the quarry face. Think about possible

consequences if these events happened and do

remember that unstable faces may not be clearly

marked as a hazard. Assess the stability of the face

yourself and do not go near the face if it appears to

be unstable.

Piles of rock & quarry waste tips

Rock piles may provide rock samples that are otherwise

inaccessible, but such piles may be unstable. There is risk

of piles collapsing and chances of you sustaining sprain

and/or crush injuries and possibly resulting in injury to

others. Assess the stability of rock piles. Keep away if they

are unstable.

Remember: In quarry waste tips there is also risk of

contact with hazardous materials which may cause burns

or illness.

Settling ponds and mud lagoons

Working (and disused) quarries may

have settling ponds or sludge

lagoons. These may appear as

pools, but more often they are

muddy ponds partly obscured by a

crusty skin (or vegetation in a

disused quarry). Always go round

these areas. There is risk of sinking

in such ponds, resulting in

entrapment, exposure, suffocation

or drowning.

Slopes & faces in pits

Slopes and faces in sand, gravel or

soft sediment pits are potential

hazards. Steep slopes may be

unstable, particularly in wet

conditions. There is risk of slumping

or collapse of faces. These may

result in burial, entrapment,

suffocation or death. Avoid climbing

such slopes and faces to reduce the

risk of avalanching material onto

others working below you in the pit.

Blasting

Blasting occurs in most hard rock quarries. On arrival at

the quarry you will normally be told about timings of

blasting, warning signals, safety procedures and the

location of safe refuges.

There is risk of injuries from shock waves, noise and

flying rock fragments. Think about the possible

consequences of these injuries.

Confrontation in quarries and pits

You are likely to find yourself in a

confrontational situation in a working quarry

if you haven't obtained permission to enter

or have placed yourself in danger by ignoring

safety instructions. You will be excluded from

the site. To avoid further embarassment you

must respond calmly and leave the site

immediately if requested to do so by

someone in authority.

Conveyors and crushers

Entrapment and high noise levels

are risks associated with conveyors

and crushers. These pieces of

equipment are noisy and you may

find it difficult to hear safety

instructions or end up with

temporary loss of hearing.

Fractured limbs, crushing and

death can occur as a result of limbs

and clothing becoming trapped in

the moving parts of conveyors and

crushers. Stay clear of moving

equipment. Never touch controls

and do not attempt to pick samples

from a moving conveyor.

This is a view of a disused slate quarry in Snowdonia.

Many of the hazards associated with working quarries may be seen here.

You must ensure that you wear a safety helmet in abandoned quarries and good quality

boots with firm ankle support and good toe protection.

Click on each hotspot to remind yourself about these hazards and to find out about additional

hazards in abandoned quarries.

Disused quarries - hazards

Disused quarries - additional hazards

These images highlight some of the additional hazards presented by disused quarries.

When you are working in disused quarries you must always:

•

wear a safety helmet

•

wear good quality walking boots with good ankle support

•

assess the stability of the quarry face

•

beware of animals and nesting birds on the quarry ledges.

Quarry used as a landfill site

This is a quarry in Storeton, Wirral. Sandstone was quarried at this site, but after the quarry was closed it was used as a landfill site. Some of the materials dumped in old quarries may be hazardous and you should avoid contact with rusty metal or leaking containers to avoid risk of flesh wounds, burns and skin or eye irritation. Note the additional hazards in this quarry where there are overgrown areas and steep rock faces.

Unstable quarry faces

This shows Park Hall Quarry in

Staffordshire. Originally the

quarry was mainly worked for

the pebble beds which were used

as aggregate. Park Hall is a SSSI

(Site of Special Scientific Interest)

and National Nature Reserve

(NNR) for its geology.

Two of the hazards that are

shown in this image are:

•

steep unstable quarry faces

•

overgrown faces.

Rock falls

This is a disused limestone quarry in

North Wales.

The main hazard here is rock falling from

the steep rock faces forming unstable

piles of angular limestone fragments at

the base ot the rock faces.